Thermoforming Mold Engineering

Transforming Ideas into Reality. Harness the power of heat and precision with our Thermoforming Molds, shaping innovation with every mold.

Thermoforming Mold

What is Thermoforming Mold?

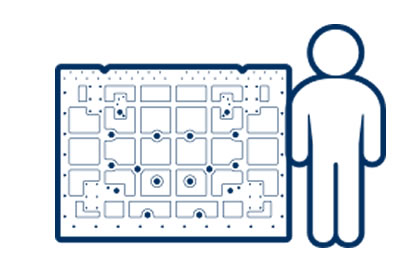

A Thermoforming Mold is an essential tool used in the thermoforming process to shape plastic sheets into specific forms. It works by heating a thermoplastic sheet until it becomes pliable and then forming it over the mold surface using vacuum, pressure, or mechanical force. Thermoforming molds enable the efficient and precise creation of various products such as packaging trays, automotive components, and consumer goods.

Precision Injection Mold

What is Thermoforming Mold Process?

Thermoforming Mold Process

The Thermoforming Mold Process involves several steps:

- Design Preparation: A detailed design of the desired product is created using CAD software, considering factors like dimensions, material thickness, and product geometry.

- Material Selection: The appropriate thermoplastic material is chosen based on the product requirements, such as durability, clarity, or heat resistance.

- Sheet Heating: A thermoplastic sheet is heated to a specific temperature until it becomes pliable and can be easily manipulated.

- Mold Positioning: The heated sheet is placed over the Thermoforming Mold, which consists of a male and female mold. The mold can be made from various materials, including aluminum or steel.

- Forming Process: The mold is closed, and either vacuum, pressure, or mechanical force is applied to shape the heated sheet around the mold contours. This process can be performed manually or using automated machinery.

- Cooling and Solidification: Once the sheet has taken the desired shape, it is cooled using air or water to solidify the plastic.

- Trimming and Finishing: Excess material is trimmed off, and any additional finishing processes, such as drilling holes or adding surface textures, may be performed.

- Product Removal: The formed product is removed from the mold, and the mold is prepared for the next cycle.

- Quality Inspection: The formed parts undergo inspection to ensure they meet the specified dimensional and cosmetic requirements.

- Packaging and Distribution: Finally, the finished products are packaged and prepared for distribution to customers.

This process allows for the efficient production of a wide range of products with varying complexities and geometries.

CNC Machining

CNC machining is a computer-controlled manufacturing process that utilizes pre-programmed software to dictate the movement of machinery and tools. This technology enables the precise cutting, drilling, and shaping of materials such as metal, plastic, and wood to create intricate components with high accuracy and consistency.

Read More

Precision Grinding

Precision grinding is a manufacturing process that involves the removal of material using abrasives to achieve extremely tight tolerances and surface finishes. used to produce components with intricate shapes, precise dimensions, and smooth surfaces. Precision grinding techniques include cylindrical grinding, surface grinding, and internal grinding.

Read More

Electrical Discharge Machining

Electrical Discharge Machining (EDM) is a non-traditional machining process that utilizes electrical discharges to erode material from a workpiece. It is particularly useful for machining complex shapes and hardened materials that are difficult to machine with conventional methods. EDM can achieve high precision and surface quality.

Read MorePrecision machining and manufacturing involve the use of advanced techniques and equipment to produce highly accurate and intricate components with tight tolerances. It requires expertise in machining processes, material properties, and quality control methods to ensure the production of high-quality parts for various industries.

Key Aspects of Understanding Injection Molds

- Design Principles: Understand the principles of injection mold design, including considerations for part geometry, material flow, cooling, and ejection.

- Materials and Construction: Explore the materials commonly used in injection mold construction, such as tool steel, aluminum, and beryllium copper.

- Manufacturing Techniques: Gain insights into the manufacturing processes used to produce injection molds, including machining, EDM, and CNC milling.

- Mold Maintenance and Repair: Learn about the importance of mold maintenance and preventive maintenance schedules to ensure the longevity and performance of injection molds.

- Tooling Standards and Regulations: Familiarize yourself with industry standards and regulations related to injection mold design and manufacturing.

- Advanced Technologies: Stay informed about advancements in injection mold technology, such as rapid prototyping, additive manufacturing (3D printing), and simulation software.

- Cost Considerations: Gain insights into the cost factors associated with injection mold production and learn about strategies for cost optimization.

- Case Studies and Best Practices: Study real-world examples of successful injection mold projects across various industries.

Key Aspects of Understanding Precision Machining

- Processes and Techniques: Explore the various precision machining processes and techniques, including turning, milling, drilling, grinding, electrical discharge machining (EDM), and others.

- Materials: Learn about the different types of materials commonly machined using precision techniques, such as metals (e.g., aluminum, steel, titanium), plastics, ceramics, and composites.

- Tooling and Equipment: Familiarize yourself with the cutting tools, machine tools, and equipment used in precision machining.

- Tolerances and Metrology: Gain insights into tolerance requirements and metrology techniques used to measure and verify part dimensions and surface characteristics.

- Design for Manufacturing (DFM): Explore principles of design for manufacturability (DFM) and how they apply to precision machining.

- Quality Assurance: Understand quality control measures and inspection techniques used in precision machining.

- Applications and Industries: Explore the diverse applications of precision machining across industries such as aerospace, automotive, medical, electronics, and tooling.

- Advanced Technologies: Stay informed about advancements in precision machining technology, including automation, robotics, additive manufacturing (3D printing), and advanced materials.

Precision machining and mold technical documents

Other Downloads

- Technical Parameter 3.9 MB

- Technical Drawing 1.8 MB