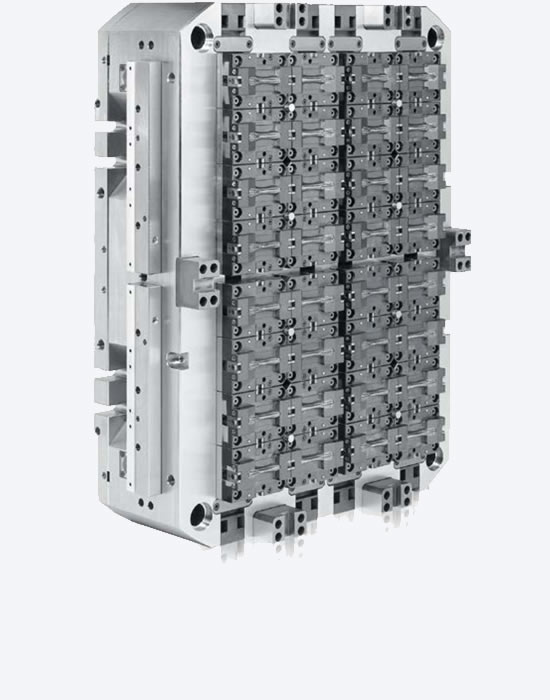

INJECTION MOLD

What is injection mold?

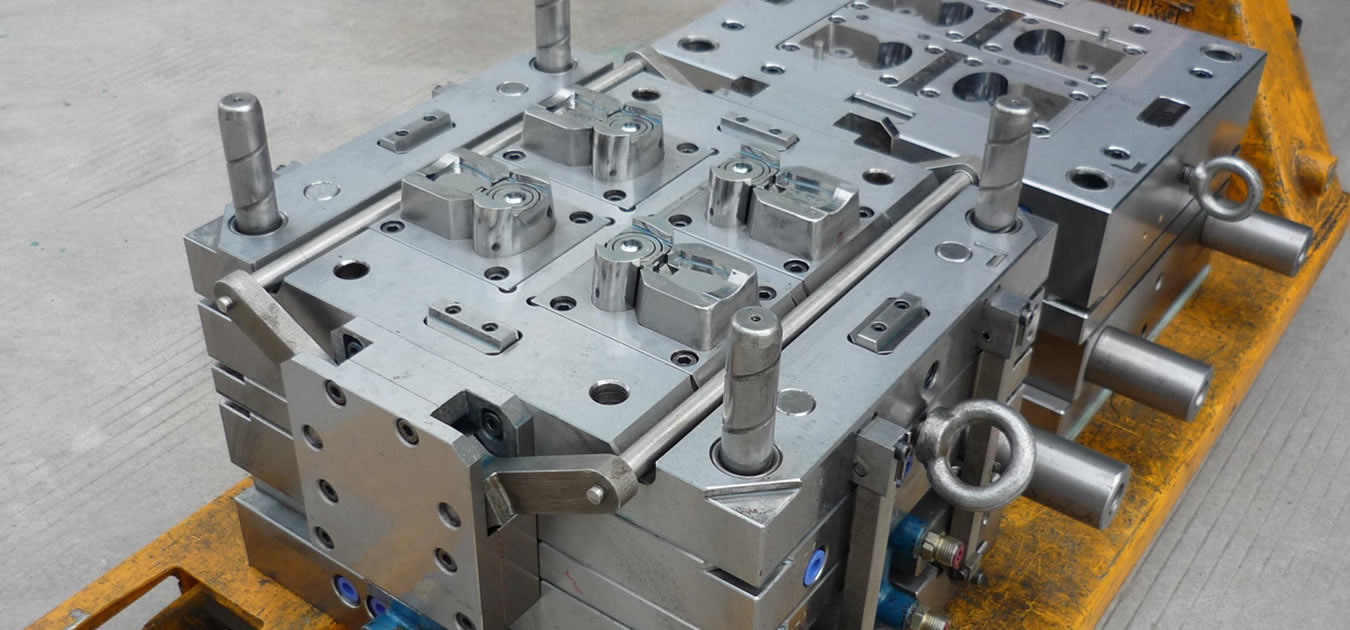

An injection mold is a specialized tool used in the manufacturing process of injecting molten material, typically plastic, into a mold cavity. This cavity, shaped according to the desired product, allows the molten material to cool and solidify, forming the final product. Injection molds are precision-engineered to ensure accurate reproduction of intricate details and dimensions.

As a leading precision machining and mold manufacturing company in China, we excel in delivering top-notch solutions tailored to your exacting specifications. With cutting-edge technology and unparalleled expertise, we provide precision, reliability, and innovation in every component we produce.

Precision Injection Mold Manufacturing

What is Injection Molding Process?

Injection Molding

1. Mold Preparation: The process starts with the preparation of the mold, which consists of two halves (the cavity and the core). These halves are mounted inside the injection molding machine.

2. Material Feeding: The raw material, usually in the form of small pellets or granules, is fed into the injection molding machine's hopper. The material is then heated to a molten state within the machine's barrel.

3. Injection: Once the material is molten, it's injected into the mold cavity under high pressure. The pressure ensures that the material completely fills the mold and takes its shape.

4. Cooling: After the mold cavity is filled, the molten material is allowed to cool and solidify within the mold. Cooling can be accelerated through the use of cooling channels within the mold.

5. Ejection: Once the material has solidified, the mold opens, and the finished part is ejected from the mold cavity. Ejection can be assisted by pins, air blasts, or other mechanisms.

6. Cycle Repeat: The above steps are repeated for each cycle of the injection molding process. The cycle time varies depending on factors such as the material being used, the complexity of the part, and the size of the mold.

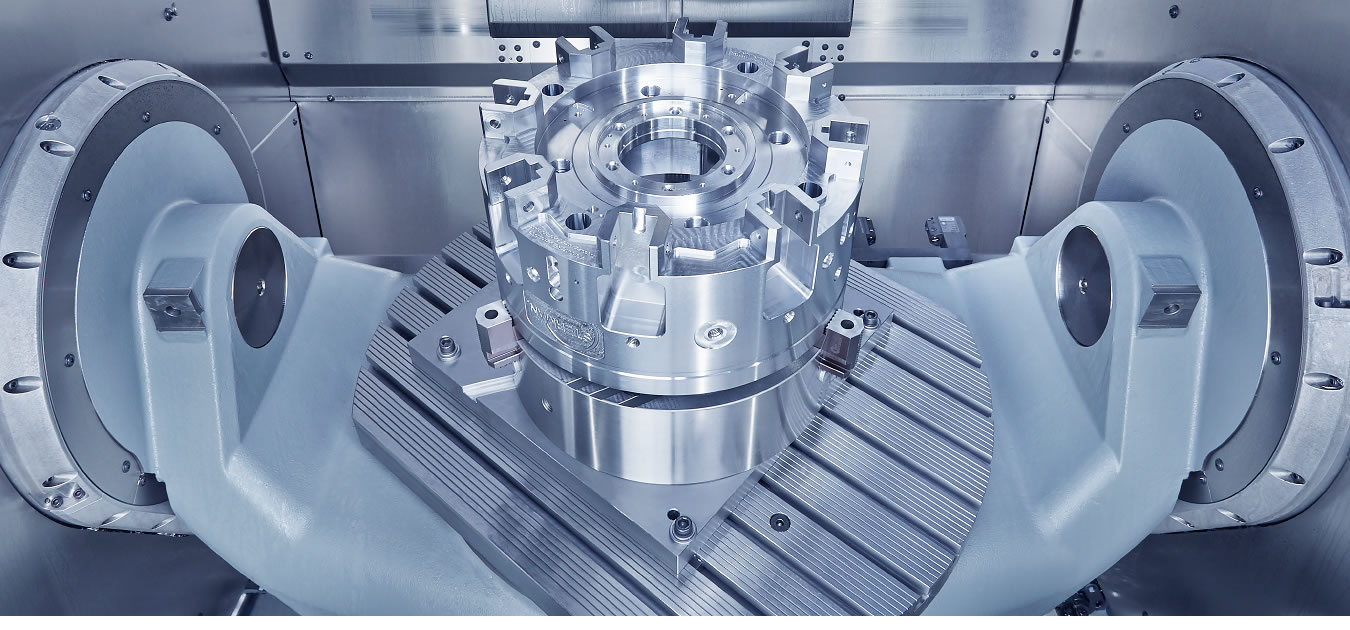

CNC Machining

CNC machining is a computer-controlled manufacturing process that utilizes pre-programmed software to dictate the movement of machinery and tools. This technology enables the precise cutting, drilling, and shaping of materials such as metal, plastic, and wood to create intricate components with high accuracy and consistency.

Read More

Precision Grinding

Precision grinding is a manufacturing process that involves the removal of material using abrasives to achieve extremely tight tolerances and surface finishes. used to produce components with intricate shapes, precise dimensions, and smooth surfaces. Precision grinding techniques include cylindrical grinding, surface grinding, and internal grinding.

Read More

Electrical Discharge Machining

Electrical Discharge Machining (EDM) is a non-traditional machining process that utilizes electrical discharges to erode material from a workpiece. It is particularly useful for machining complex shapes and hardened materials that are difficult to machine with conventional methods. EDM can achieve high precision and surface quality.

Read More

25

Export to 25+ countries

200

200+ Employees

50

Patent for Invention

1000

Annual Capacity (Set)

WHY CHOOSE US

Customized Solutions for Your Unique Needs!

Unlock the potential of precision machining with our cutting-edge solutions. From intricate components to complex molds, we deliver excellence in every detail. Trust us to bring your vision to life with unparalleled accuracy and reliability.

At our company, customization is our forte. We tailor our services to meet your specific requirements, ensuring a perfect fit for your projects. With our flexible approach and unwavering commitment to quality, we guarantee satisfaction every time.

MOLDING SOLUTIONS

Precision machining and molds: shaping perfection!

Our precision grinding tools boast unparalleled accuracy, ensuring every detail meets exact specifications. With advanced technologies and skilled craftsmanship, we deliver components with precise tolerances, empowering industries to achieve peak performance and reliability in their products.

Unrivaled Precision

Engineered to withstand rigorous demands, our precision grinding tools are crafted from premium materials and undergo stringent quality control measures. From intricate molds to intricate components, our tools endure the toughest conditions, guaranteeing longevity and resilience in every application.

Exceptional Durability

Versatile Solutions: Offering a comprehensive range of precision grinding solutions, we cater to diverse industries and applications. Whether it's aerospace, automotive, or medical sectors, our customizable tools adapt to various materials and complexities, providing versatile solutions tailored to meet every unique requirement.

Versatile Solutions

Precision machining and manufacturing involve the use of advanced techniques and equipment to produce highly accurate and intricate components with tight tolerances. It requires expertise in machining processes, material properties, and quality control methods to ensure the production of high-quality parts for various industries.

Key Aspects of Understanding Injection Molds

- Design Principles: Understand the principles of injection mold design, including considerations for part geometry, material flow, cooling, and ejection.

- Materials and Construction: Explore the materials commonly used in injection mold construction, such as tool steel, aluminum, and beryllium copper.

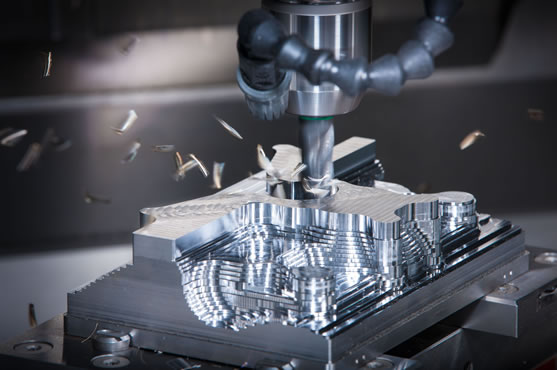

- Manufacturing Techniques: Gain insights into the manufacturing processes used to produce injection molds, including machining, EDM, and CNC milling.

- Mold Maintenance and Repair: Learn about the importance of mold maintenance and preventive maintenance schedules to ensure the longevity and performance of injection molds.

- Tooling Standards and Regulations: Familiarize yourself with industry standards and regulations related to injection mold design and manufacturing.

- Advanced Technologies: Stay informed about advancements in injection mold technology, such as rapid prototyping, additive manufacturing (3D printing), and simulation software.

- Cost Considerations: Gain insights into the cost factors associated with injection mold production and learn about strategies for cost optimization.

- Case Studies and Best Practices: Study real-world examples of successful injection mold projects across various industries.

Key Aspects of Understanding Precision Machining

- Processes and Techniques: Explore the various precision machining processes and techniques, including turning, milling, drilling, grinding, electrical discharge machining (EDM), and others.

- Materials: Learn about the different types of materials commonly machined using precision techniques, such as metals (e.g., aluminum, steel, titanium), plastics, ceramics, and composites.

- Tooling and Equipment: Familiarize yourself with the cutting tools, machine tools, and equipment used in precision machining.

- Tolerances and Metrology: Gain insights into tolerance requirements and metrology techniques used to measure and verify part dimensions and surface characteristics.

- Design for Manufacturing (DFM): Explore principles of design for manufacturability (DFM) and how they apply to precision machining.

- Quality Assurance: Understand quality control measures and inspection techniques used in precision machining.

- Applications and Industries: Explore the diverse applications of precision machining across industries such as aerospace, automotive, medical, electronics, and tooling.

- Advanced Technologies: Stay informed about advancements in precision machining technology, including automation, robotics, additive manufacturing (3D printing), and advanced materials.

Precision machining and mold technical documents

Other Downloads

- Technical Parameter 3.9 MB

- Technical Drawing 1.8 MB